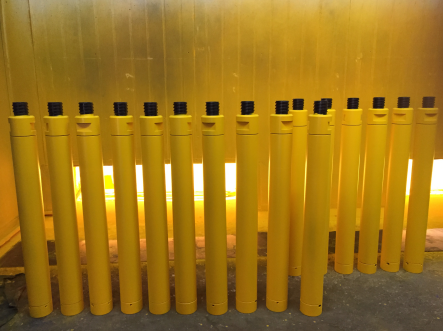

Here is Dth Hammer Drilling Manufacturer talking about similarities between electroplating and vacuum brazing.

If you have any idea about Dth Hammer Bits, welcome to contact us and discuss.

Before we get into the differences, let's see where there are some similarities. In contrast to both resin and sintered bonds, where the diamond grit is suspended within a matrix, electroplating and vacuum brazing are manufacturing techniques where the diamond is fully exposed. Without a matrix required to wear or erode, the diamond grit immediately attacks the working surface. This direct contact with the material makes electroplating and vacuuming brazing very aggressive.

Electroplating and vacuum brazing tools have a much higher concentration of diamond. The working surface or edge is fully concentrated with diamond grit. The diamond grit in resin and sintered bonds are like chocolate chips in a cookie. The diamond in electroplating and vacuum brazing is more like a chocolate bar, all chocolate. Silly analogy, but it gets the point across, no? We’ll be quick to point out that both are good depending on the application.

Though electroplating and vacuum brazing have similar characteristics, their vastly different manufacturing processes result in some important microscopic differences.

We are Dth Drilling Tools Supplier, if you are interested, please inform us.

Copyright © Guiyang Top Equipment All Rights Reserved

Sitemap | Powered by